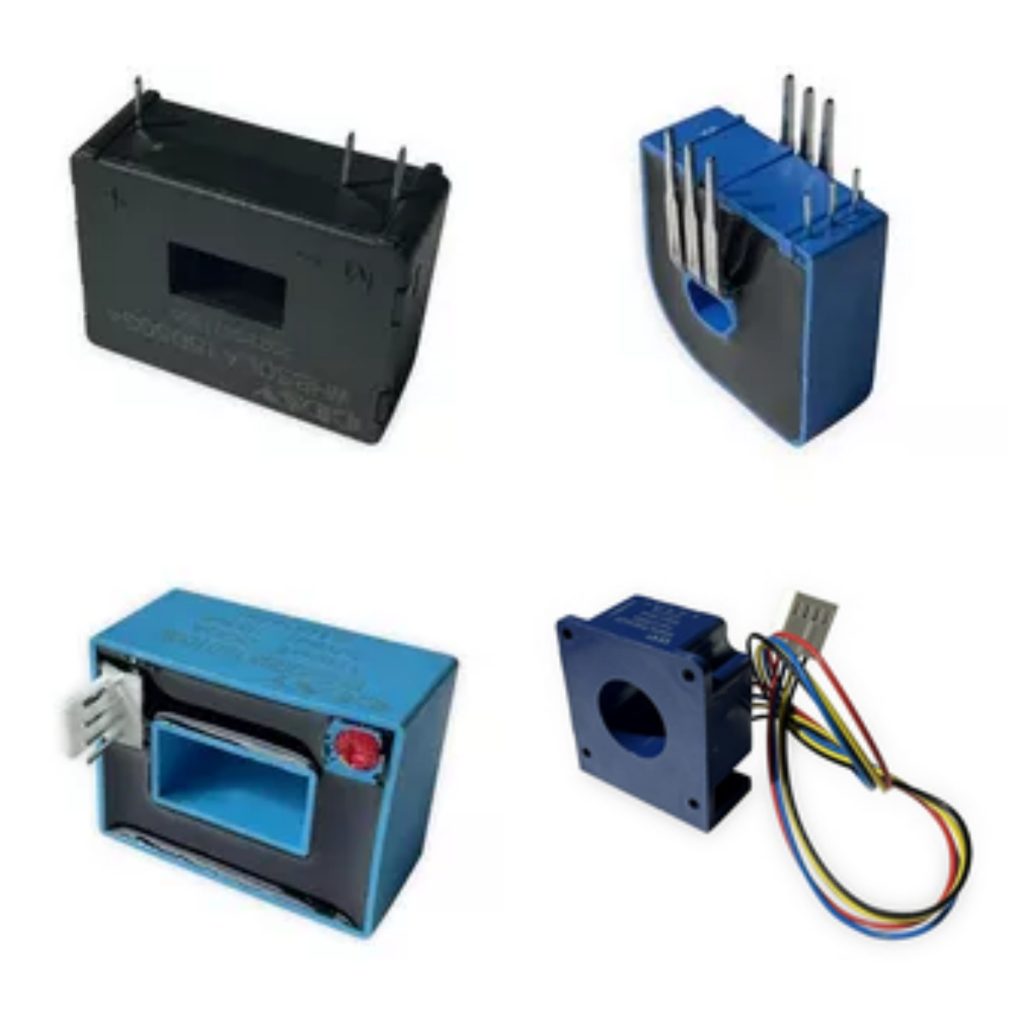

Overview

Hall effect current sensors are key measuring components in modern power electronics systems. Their reliability directly impacts the overall system’s operational safety and measurement accuracy. This article will analyzes four major failure modes of Hall effect current sensors: Hall element performance degradation, core saturation and magnetic property degradation, signal processing circuit failure, and packaging and connection failure. It thoroughly explores the manifestation characteristics, mechanisms, and influencing factors of each failure mode. By optimizing material selection, improving chip design, refining manufacturing processes, and strengthening quality control, premature failure of Hall effect current sensors can be effectively prevented and providing more stable current measurement for power electronics.

1.Hall effect element performance degradation is the failure mode at most affecting measurement accuracy.

Hall effect element performance degradation primarily manifests as zero drift, decreased sensitivity, and deteriorated linearity, resulting in significant deviations from specification. The root causes of this failure are the temperature sensitivity of semiconductor materials. The Hall effect element’s temperature coefficient causes sensitivity to vary with temperature while material defects and interface states increase low-frequency noise and long-term drift. During the manufacturing process, uneven ion implantation and imperfect annealing can cause a decrease in carrier mobility and accelerate performance degradation. To prevent such failures, temperature compensation circuits must be implemented during the design phase, and Hall materials and signal conditioning chips with matching temperature coefficients must be selected. Doping concentrations and annealing parameters must be strictly controlled during the production process to ensure uniformity and stability of the Hall element. Thermal management should be considered in package design to reduce the chip’s operating temperature. The long-term stability of Hall current sensors can be significantly improved by employing a differential Hall element structure and advanced temperature compensation algorithms.

2.Core Saturation and Magnetic Property Degradation Lead to Measurement Distortion

Core saturation and magnetic property degradation manifest as a reduction in measurement range, output signal distortion, and increased phase error, severely impacting dynamic measurement performance. The primary mechanisms of this failure are magnetic saturation of the core material due to overcurrent or strong external magnetic fields as well as magnetic aging after long-term use. The decrease in the core material’s magnetic permeability and increase in its coercivity reduce its magnetic concentrating capacity affecting sensor sensitivity. Temperature changes can also alter the core’s magnetic properties especially at high temperatures. To prevent this type of failure, the design should carefully select core materials to ensure sufficient magnetic saturation margin, using high-permeability, low-loss nanocrystalline or Permalloy materials. Structural design can use segmented cores to avoid local saturation. During production, strict control of heat treatment processes should be implemented to optimize the core’s magnetic properties. Adding overcurrent protection circuits and magnetic shielding can effectively prevent core saturation caused by external interference.

3.Signal Processing Circuit Failures Causing System-Level Failures

Signal processing circuit failures manifest as abnormal output signals, communication interruptions directly impacting sensor operation. This failure mode involves multiple aspects, including the amplifier circuit, filter circuit, ADC converter, and output driver circuit. Primary causes include electronic component aging, power supply fluctuations, electromagnetic interference, and electrostatic discharge. Op amp offset voltage drift and resistor value variations can lead to accumulated measurement errors while power supply noise and ground line interference can reduce the signal-to-noise ratio. To prevent this type of failure, circuit design should incorporate redundancy, selecting high-reliability, low-temperature drift electronic components. Strengthen power management and filtering design, implement watchdog circuits and implement fault diagnosis functions. Improve electrostatic protection measures during production, and strictly control soldering quality and cleaning processes. Implementing rigorous online testing can detect potential faults early and improve the reliability of signal processing circuits.

4.Packaging and Connection Failures Affect Mechanical Integrity

Packaging and connection failures manifest as housing damage, lead breakage, seal failure, and internal moisture, leading to sensor loss of function or performance degradation. The primary cause of these failures is the combined effects of mechanical stress, thermal stress, and environmental factors. A mismatch in the thermal expansion coefficients between the packaging material and the chip generates thermal stress, leading to interface delamination due to long-term temperature cycling. Vibration and shock can cause fatigue fractures in solder joints, while moisture intrusion can trigger electrochemical corrosion and insulation degradation. To prevent these failures, package design should select materials with matching thermal expansion coefficients, optimize structural strength, and enhance sealing performance. Flexible connections and stress buffers should be used to absorb mechanical stress. The quality of the encapsulation compound, welding parameters, and sealing techniques must be strictly controlled during production. Strengthen environmental adaptability design, including moisture, vibration, and corrosion protection measures.

Conclusion

Failure mode analysis of Hall effect current sensors provides an important basis for improving product reliability. Failure prevention requires a systems engineering approach, encompassing comprehensive optimization from the chip level, circuit level, to the system level. Establishing a comprehensive failure analysis database and prevention mechanisms is crucial for promoting technological advancement and improving product quality in the industry.